Few industries are growing as rapidly as construction 3D printing. The sector is predicted to become a $40bn market by 2027 and several companies are working round the clock to be part of the boom.

We’ve seen a race to create the first house 3D printers that can reliably and quickly build hundreds of 3D printed houses at low prices, achieving feats impossible through traditional construction methods.

This guide will showcase the most innovative construction 3D house companies, sharing how their successes from entire offices, government buildings and beautifully designed homes.

Quick Overview

- Icon – Space Research & Philanthropic Housing

- Apis Cor – Speedy Construction & The Largest 3D Printed House

- CyBe – Printer Mobility for Hard to Reach Places

- WASP – Sustainable Construction from Eco-Friendly Materials

- WinSun – 3D Printed Ten Houses in Just One Day!

- Be More 3D – Designed to Thrive in Hot and Harsh climates

1. ICON

- Based in: United States

- Best known for: Austin, Texas 3D printed house

- Learn more here

ICON are not just a 3D printing company, but also focuses on robotics and traditional construction projects. Based in the USA, ICON are backed by Paul Graham’s legendary tech incubator and investment wing Y Combinator, and have ambitious goals to build exciting buildings all over the world with their powerful Vulcan II house 3D printer.

ICON collaborated with New Story to build a simple yet smart home in Austin, Texas, costing $4,000 to build. Since then, ICON has moved on to creating homes in Mexico, and in 2020 secured $35M to commercialize 3D printed home building technologies, taking their total investment to $44M.

Vulcan II house 3D printer

ICON’s Vulcan II house 3D printer is a gigantic concrete-extruding goliath capable of building up to 2,000 square feet homes. Among the first commercially available construction 3D printers, the Vulcan II is specifically designed to build resilient single-story homes up to 8.5 feet tall and 28 feet wide.

ICON have also pioneered research into their concrete-based material to prevent it creating imperfect layers or hardening too quickly. The actual material mix itself can be altered based on needs and uses, making ICON’s offering versatile and changeable based on the local environment.

Project Olympus

In late 2020, Icon received funding from NASA to develop 3D printing technology for different projects on the moon. Dubbed “Project Olympus“, this partnership between NASA and ICON aims to construct living spaces, roads, and launch pads on the moon.

And the best part is that the project will source all raw materials directly from the moon’s surface and print them using a revolutionary 3D printer that ICON is developing.

The $57.2 million project is part of NASA’s Artemis program that aims to enable human habitation of the moon. It also turns out that ICON is no stranger to 3D printed space technology, having already collaborated with NASA on the Mars Dune Alpha, a 3D printed habitat that simulates what living on Mars would feel like.

Community First! Village

Back here on earth, ICON has extended its business horizon to include housing philanthropy. Under the Community First! Village, the company 3D printed six 400-square foot homes for people that have gone through chronic homelessness. Each home includes a living room, bedroom, bathroom, kitchen, and porch.

ICON’s Vulcan II printer 3D printed each of these homes with support from Texas nonprofit, Mobile Loaves & Fishes (MLF). In the spring of 2020, a group of individuals moved into the homes, making them the first people to live in a 3D printed house in the U.S.

Genesis Collection

Following the success of the Community First! Village, ICON launched the Genesis Collection, a housing project of 100 3D-printed family homes.

The Genesis Collection is arguably the most ambitious 3D printed home project to date. According to ICON co-founder and CEO, Jason Ballard:

“For the first time in the history of the world, what we’re witnessing here is a fleet of robots building an entire community of homes. And not just any homes, homes that are better in every way… better design, higher strength, higher energy performance and comfort, and increased resiliency…”

Together with U.S homebuilding giant Lennar, ICON began construction of the homes in 2021 at Wolf Ranch in Georgetown, Texas with the purpose of creating more affordable housing.

The homes are designed by the Bjarke Ingels Group (BIG) and prices range from $450,000 to $600,000, serving a blend of modern architecture and innovative construction technology. With over $451 million raised since it was founded, Icon has led the charge in the 3D printed home construction industry.

House Zero

Meanwhile, another ICON project, House Zero, has been making headlines for pushing the boundaries in the 3D printed home construction industry. Located in East Austin, House Zero is a 3-bedroom house that was constructed with significantly less time, cost, and waste than traditional building methods.

ICON’s Vulcan construction system 3D printed the walls of House Zero in less than two weeks using a proprietary cement-like material, insulation, and reinforced steel. Using only these 3 raw materials, this process drastically cuts down construction times and raw materials.

House Zero honors the adage of “form follows function”. Its curved walls, rounded corners, and large open spaces give the house a modern architectural look. Cleverly placed doorways and windows bring in more sunlight, giving the interior and aesthetic appeal while reducing the need for artificial daytime lighting.

From TIME’s Best Inventions of 2022 to Builder’s Magazine’s Project of the Year, ICON has won multiple awards in the design and architecture category, signaling a bright future of reduced home construction expenses.

East 17th Street

The East 17th Street Residences in East Austin are another member of ICON’s family of 3D printed homes. Designed by Logan Architecture, the houses are the first 3D-printed homes for sale in the U.S.

The residences consist of four unique 2- and 4-bedroom houses standing on either 925 square feet or 1,928 square feet. Still constructed with ICON’s Vulcan construction technology, the walls for all four houses took one week to 3D print, which would typically take much longer traditionally.

Currently, two houses have been sold, and the remaining ones go at around $745k and $795k, depending on the prevailing real estate market.

2. Apis Cor

- Based in: United States

- Best known for: 3D printing an entire house in 1 day!

- Learn more here

American company Apis Cor famously 3D printed an entire house in just a single day back in December 2016, going viral and commanding worldwide attention for this extraordinary feat. Located in the Russian town of Stupino, the igloo-style house was the first 3D printed residential house, completed with the help of PIK, a Russian real estate company. Since then, Apis have won NASA prizes for potential space 3D printing techniques for creating structures on Mars.

Then in 2019, Apis Cor made headlines again when they built the largest 3D printed house in the world, a huge building in Dubai to be used for administrative purposes. The building took 17 days to print and encompasses 640m2. Having built houses in Russia’s tough winter climate as well as hot Dubai, Apis Cor have proven they can create durable 3D printed houses anywhere.

Their house 3D printers are huge goliath structures, with a 4.5-meter-long polar 3D printer specifically built for concrete extrusion. It can be set up in 30 minutes, depositing concrete layer-by-layer to create a full house structure. These house 3D printers only create the structure however — the equivalent of a car chassis — that skilled workers can then finish by adding plumbing and electrical systems.

3. CyBe Construction

- Based in: Holland

- Best known for: Milan Design Week 3D Printed House

- Learn more here

CyBe is another hugely innovative company in the 3D printed house sector. Responsible for the house showcased during Milan Design Week, as well as 3D printed bridges in the Netherlands and concrete buildings built in Saudi Arabia, CyBe Construction are making huge progress in building habitable houses using their concrete 3D printers.

The Dutch house 3D printer company has two construction 3D printer models, the CyBe RC 3Dp, and CyBe R 3Dp, able to print structures quickly at up to 200mm/s. They also use patented materials based on concrete mix, and claim they can fully construct houses for under $100,000.

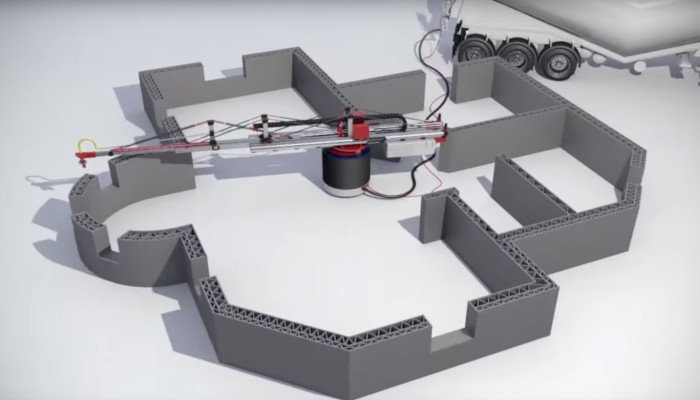

These construction 3D printers are unique in that their tank-like tracks allow them to move around building sites and positioning themselves to deposit concrete. Like Apis Cor, CyBe house 3D printers are active in Dubai, having built buildings that are to be used for drone R&D, as well as in India and Japan.

At the moment, CyBe’s fleet of large 3D printers includes four models:

- CyBe R

- CyBe RC

- CyBe RT

- CyBe G

The CyBe G

Their latest model, the CyBe G, is gantry-based with a four-column, three-beam configuration, ideal for affordable housing construction. At 500 mm/s, the CyBe G boasts of one of the fastest printing speeds for 3D printed house construction.

The printer works by allowing large components to be printed in a factory setting and assembled on-site to complete the full building. This method, called Prefabricated Prefinished Volumetric Construction (PPVC), promises faster production times, reduced costs and higher profits for construction companies in the future.

Currently, CyBe aims to build the world’s first four-story apartment building in conjunction with Dutch housing developer, Lab040. Using the CyBe G printer, the complex is set to be constructed in the Netherlands and will feature six apartments.

This project will be a flag bearer for CyBe’s vision of “enabling companies to build faster with less resources.” The object of the construction process is to cut down gas, light and water costs to a record low and align the building with United Nations SDG 11 – Sustainable Cities and Communities.

In South Africa, CyBE is teaming up with the SAHIF (South African Housing & Infrastructure Fund) to construct the first South African 3D printed houses to bring more affordable houses in the country. Currently there is a South African housing shortage of about 2 million homes, and the joint venture hopes to create more affordable housing using a much faster, cheaper, and more automated construction process.

4. WASP

- Based in: Italy

- Best known for: Gaia sustainable house

- Learn more here

WASP (World’s Advanced Saving Project) is an Italian 3D printer manufacturer who sells a variety of desktop delta 3D printers as well as clay 3D printers for the ceramic market. These include their Delta Pro range, claimed to be the fastest 3D printers in the world.

With far larger ambitions however, WASP also has two construction 3D printers, the BigDelta and Crane WASP house 3D printers. The BigDelta is claimed to be the world’s largest 3D printer, at 12 meters tall and 7 meters wide. It’s also the face of WASP’s commitment to building sustainable, “zero-mile” homes.

Since its inception in 2012, the company has had a vision of using eco-friendly, sustainable materials and portable machinery to create green homes. As climate emergencies mount pressure on the construction industry, WASP has made bold steps by successfully experimenting with flour, sawdust and mushroom mycelium to replace concrete.

Recently, WASP built the Gaia eco-sustainable house, proving the concept and showing a sleek yet basic small house can be 3D printed with ease.

Crane Wasp

WASP’s breakthrough came in 2018 when they released the Crane WASP, the first modular, multi-stage 3D printer in the market. The 3D printing system that can be readjusted to meet the demands of small and large house construction spaces.

Modeled off classical construction cranes, the Crane WASP has a maximum printing speed of 300 mm/s and can extrude earth-based materials, concrete, and geopolymers, making it a major player in rapid sustainable home construction.

The company showcased what Crane WASP can do by constructing Gaia, the first house 3D printed from soil. WASP built the 320-square-feet house in 10 days using 25 percent soil, 40 percent chopped rice straw, 25 percent rice husk, and 10 percent hydraulic lime.

Although WASP’s primary operations are based in Italy, the company has spread its mission to other construction projects around the world. In 2021, WASP completed construction of a pop up store for fashion brand Dior.

The installation stands on the Jumeirah beach in Dubai and features several Dior collections inside wall structures that were 3D printed in sand, clay, and plant fiber.

The same story echoed in Spain when WASP constructed TOVA, the first 3D printed architectural structure in the country using mud. This came as a result of a partnership between WASP and postgraduate research students at the Institute for Advanced Architecture of Catalonia (IAAC) at Valldaura Labs in Barcelona.

5. WinSun

- Based in: China

- Best known for: 3D printing 10 houses in a day in 2014

- Learn more here

WinSun is a Chinese company which made headlines back in 2014 by building ten 3D printed houses — small concrete buildings that cost $4,800 each — in just one day. Since then WinSun have continued to innovate, 3D printing an eco-friendly bus stop in 2017, and collaborating with Elon Musk to help build the first Hyperloop tunnels.

WinSun claim to have sold more than 100 3D printed homes, using their FDM-style construction 3D printers that extrude cement and sand materials to build walls. More recently, WinSun also worked in Dubai Future Foundation to 3D print the “office of the future”, a picturesque concrete office that would look at home in Blade Runner or similar sci-fi future world.

6. Be More 3D

- Based in: Spain

- Best known for: 3D printing a house in 12 hours

- Learn more here

Spanish house 3D printer company Be More 3D was founded by four young entrepreneurs studying a variety of architecture-related disciplines at the Polytechnic University of Valencia.

Since then, they’ve built a sleek 24m2 house in Valencia, as well as a 32m2 house they 3D printed in 12 hours for the Morroco-based Solar Decathlon Africa event in 2019 – winning the prize for most innovative start-up.

They sell their very own concrete construction 3D printer, the BEM Pro 2, which can operate even in hot and harsh climates, making it great for 3D printing houses near the equator.