Just a decade ago, the thought of a color 3D printer in every home would have sounded like delusional madness. Even single-color 3D printing on basic 3D printing machines cost thousands of dollars unless you built an early RepRap 3D printer.

Now, you can turn any cheap 3D printer into a multi-color 3D printer and create stunning color prints for just a few hundred dollars. Some color 3D printers come with this ability, and the rest can be adapted using special color 3D printer adaptors. You can even buy a full-color 3D printer, offering complete CMYK color ranges of over 50,000 colors, that fit on the side of your desk.

The Best Color 3D Printers Overall

| Name and brand | Type of color 3D printer | Best place to purchase |

|---|---|---|

| Geeetech A20M | Mix color 3D printer | Amazon here |

| Geeetech A20T | Mix color 3D printer | Amazon here |

| Crane Quad | Full Color 3D printer | |

| XYZprinting Da Vinci Color | Full color 3D printer | Amazon here |

| Palette 2S | Color 3D printer adaptor | Matterhackers here |

| Prusa Multi Material Upgrade | Color 3D printer adaptor | Prusa Store |

| 3DChameleon Upgrade Kit | Color 3D printer adaptor |

We have split this article into different sections based on what you’re looking for. You can get right to that section by clicking each part below:

Standard dual extruder printers

Non-FDM, industrial technologies for full-color

Multi Color 3D Printers

Before we get to full-color 3D printers, let’s first talk multi. Multi-color 3D printers themselves aren’t one category, but include mix color 3D printers, dual extruder 3D printers, and filament splicers that you can buy as add-ons to turn your printer into a multi-color beast.

We’ll go through each type below:

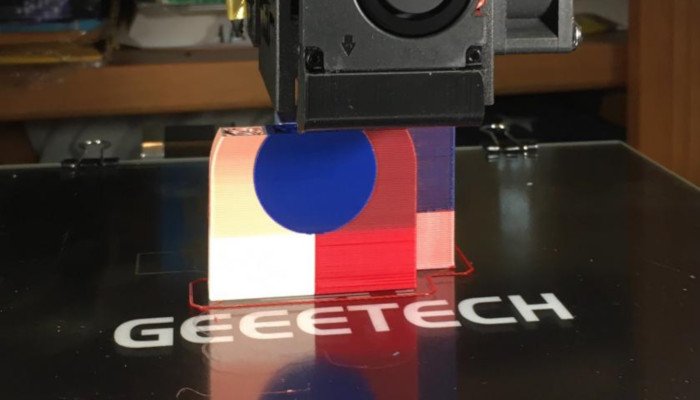

Mix Color 3D printers

Mix color 3D printers differ from dual extruder printers as rather than using two (or more) extruders and nozzles, they blend two different filaments into one nozzle, mixing the different colors together as they print.

This is cheaper than buying a multi-extruder printer, and the mix color 3D printers we recommend below are generally cheaper than dual extruder printers. However, you lose out on the main benefits of a dual extruder, such as duplication modes, and more efficient 3D printing.

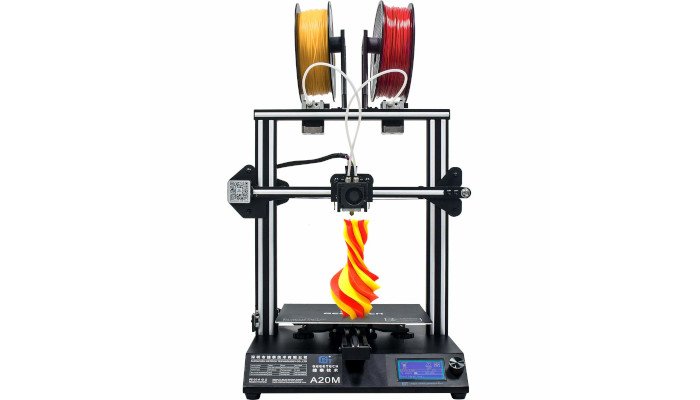

1. Geeetech A20M Mix Color 3D Printer

- Price: Check latest price at Amazon here

- Build Volume: 255 x 255 x 255 mm

- Color range: multi color 3D printers (2 colors, with mix color options)

Pros

Multiple color 3D printing options.

Very accurate.

Easy to assemble, with 3 simple steps.

Cons

Can be noisy at times.

Geeetech is a large open source 3D printer company that has sold over 100,000 3D printers worldwide. Their interesting forays into multi-color 3D printers include firstly the A20M, featuring a dual extruder with a 2 in, 1 out hot end.

This 2 in, 1 out hot end offers four different color 3D printing options: single color 3D printing, dual color 3D printing, graded color 3D printing, and mix color 3D printing. For example, for some projects you may want to print small details in a different color, whereas for some models you may want the colors to mix every few layers, or have the bottom half one color and top half another. The Geeetech A20M gives you all that flexibility.

It’s a 3D printer kit that you’ll have to assemble yourself, but does not take much DIY skill. The building process involves just 3 fairly simple steps, and the structure design is based on the Prusa for stability and quality. The Geeetech A20M is accurate, with up to 0.1mm accuracy, and also versatile in the 3D printer filaments it can use, with the ability to print not just ABS or PLA, but also wood-filled filaments, PVA, HIPS, PETG and more.

To mix colors, simply use Geeetech’s ColorMixer software, and choose your color 3D printer settings, such as graded color between certain layers. The A20M is compatible with 3D slicers like Cura and Simplify3D, and you can print remotely using the printer’s WiFi connectivity. Overall, it’s a great cheap 3D printer offering a way into color 3D printing without breaking the bank.

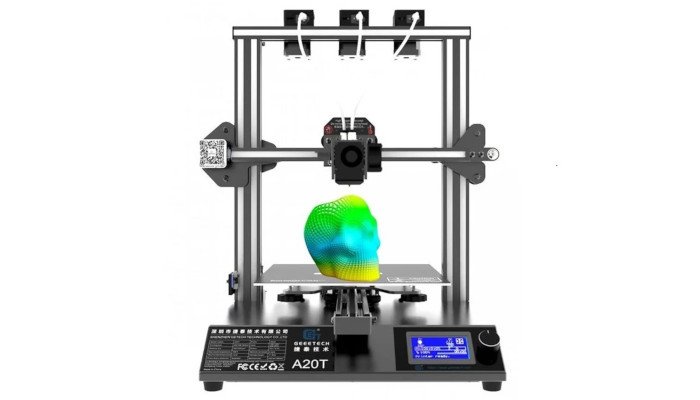

2. Geeetech A20T

- Price: Check latest price at Amazon here

- Build volume: 250 x 250 x 250 mm

- Color range: multi color 3D printer (3 colors, with mix color options)

Pros

Can mix 3 colors with this machine.

Easy to assemble.

Can remotely control it with Geetech’s EasyPrint 3D app.

Cons

Can be too complex for some.

If you thought the A20M was neat, the A20T takes that even further. Instead of being able to mix 2 colors, the A20T can mix 3, with the 3-in-1 mixing capability able to combine 3 different filament colors to create multi-colored 3D prints that look amazing.

Combining two colors can already create stunning color 3D prints, but adding a third exponentially increases design possibilities. Geeetech show examples of radiant multi color 3D prints with alternating colors on the bottom half, with a third block color on the top half, creating fantastic multi-colored models for under $500.

Again, it is based on a Prusa-inspired design, and is easy to assemble from kit form in 3 simple steps (lots of threes here!). You can use Geeetech’s EasyPrint 3D app for remote color 3D printing and monitoring, as well as giving you access to over 50,000 free 3D models to print. You can use Repetier-Host, or use Cura, as well as EasyPrint 3D.

It is ever so slightly smaller than the A20M (by 5mm on each axis) and prints with an accuracy of 0.1-0.2mm. Overall, we think the Geeetech A20T is a great multi color 3D printer to create great FDM prints with mixes of three colors in one.

3. Crane Quad

- Price: $899

- Build volume: 230 x 230 x 250 mm

- Color range: multi color 3D printer / full color 3D printer depending on settings

Pros

Takes up to four filaments at once.

Large build volume.

It comprises of over 50,000 different colors.

Cons

Flimsy.

The Crane Quad is a color 3D printer made by M3D, who previously released the successful Micro 3D printer after raising an astonishing $3.4 million on Kickstarter. The Crane Quad takes up to four filaments at once, which you can print individually and switch if you want to change color, or if you use M3D’s CMYK filaments, can combine them all together to create full color 3D prints comprising of over 50,000 different colors.

The ability to print accurately (up to a claimed 25 microns) and with such color range makes the Crane Quad a very interesting 3D printing option. The large 3D printer build volume means that large full color 3D prints can be created, and it’s also fairly portable, weighing just 8.5kg. Though far less known than the other color 3D printers mentioned, the Crane Quad is definitely an option worth considering.

Dual extruder printers with two different colored filaments

Similar to mix color 3D printers, dual extruder printers can use either two different colored filaments, or two different materials, simultaneously, due to a second nozzle and extruder. There are standard dual extruder printers, and IDEX printers, with a dual extruder that can move independently for added efficiency.

Rather than mixing filaments together, you can print models with two different colors applied on to the same model. It also means you can print soluble supports (PVA for PLA, or HIPS for ABS) that can be easily dissolved afterwards for stunning models without any of the imperfections you can get during normal post-processing.

Any dual extruder printer can 3D print with multiple colors, but here are some we recommend:

- Flashforge Creator Pro 2 — Available on Amazon here / Flashforge here

- Raise3D E2 — Available at Matterhackers here / Dynamism here

- Ultimaker S3 — Available at Matterhackers here / Dynamism here

- Ultimaker S5 — Available at Matterhackers here / Dynamism here

Filament Splicers for Multi-Color 3D Printing

Multi-color 3D printing is possible if you use a filament splicer, such as the Palette 2S, which we recommend as the number one option for multi color 3D printing.

Prusa also offers a Multi Material Upgrade kit with similar features.

These color 3D printing adaptors take up to 4 separate filaments of different colors, at once. These filaments all feed into the filament splicing machine. Prior to printing, you select which parts of your model are to be which color in Palette’s CANVAS 3D CAD software, and as the filaments are fed into the Palette filament splicer, it splices these filaments into one, multicolored spool based on which colors are to be printed in each exact area of your model.

The results are stunning, multi-color 3D prints that have many real-world uses. Interior design models can be produced at a fraction of the price, and in record time, as well as video game or film characters, 3D printed miniatures for games like Warhammer, and a huge number of other applications.

You are restricted to four different colors, or three colors and a support material, so bear in mind that these parts are not full color. You do however retain the bold colors of your chosen filaments, which in full-color 3D printing can look washed out and less striking.

4. Palette 2S & 2S Pro

- Price: Varies for Palette 2S — Available on Matterhackers here / Available on Amazon here

- Varies for Palette 2S Pro — Available on Matterhackers here / Available on Amazon here

- Color range: multi color 3D printing with up to 4 colors

Pros

Compatible with many 3D printers.

Works with a variety of filament types.

Creates stunning high-quality prints.

Cons

The initial investment cost may be too high.

Mosaic Manufacturing has stormed the industry recently with their revolutionary Palette color 3D printer filament splicers, turning any desktop 3D printer into a multi color 3D printer able to print models in up to 4 different colors or materials.

While not a 3D printer, the Palette 2S and 2S Pro connect to your printer, and splice multiple different filaments into one continuous, multi-colored filament based on the dimensions and chosen colors for that model. It calculates perfectly the amount of each color for each chosen area, splicing the filament together where that filament will be used, creating stunning multi-color 3D prints with ease.

Name a 3D printer, it’s probably compatible with the Palette 2S. Creality, Flashforge, Dremel, Makerbot Replicator, all Ultimaker 3D printers if you purchase the adaptor for 2.85mm filaments, Makergear, Qidi Tech, Prusa, Lulzbot and many other manufacturer’s 3D printers work with the Palette adaptor.

You can use the Palette 2S to create multi color 3D prints with any single materials, including PLA, ABS, TPU, PETG, PVA and Nylon, or sacrifice one color and use a soluble filament like PVA in addition to your 3 colors for soluble supports that can be dissolved. Effectively, this adaptor turns your printer – even if it previously had just a single extruder – into one with four independent extruders.

Mosaic Manufacturing also sell the Palette 2S Pro, which includes an extended warranty, extra spare parts, and better splicing capabilities. You can also buy an adaptor which allows the Palette to work with Ultimaker 3D printers that use 2.85mm filament, rather than the standard 1.75mm.

Mosaic also offer their specially designed CANVAS 3D modeling software. You can directly color and paint prints in the software before printing, that your printer will then follow to your exact specifications.

Overall, the Palette and its accompanying software open up the possibility for a huge variety of colorful 3D printing, for character models for use in film, video games and other media, as well as high added value industries like architectural models for interior design that previously would have cost far more to print on a PolyJet 3D printer.

5. Prusa Multi Material Upgrade 2S

- Price: $299 — Available on Prusa store here / Prusa i3 MK3S+ available here

- Color range: multi color 3D printer (up to 5 different colors)

Pros

Affordable.

Reliable and produces high-quality prints.

A filament buffer is included to keep each filament separate from others.

Cons

Only works with Prusa printers.

Not compatible with TPU and Nylon.

Prusa 3D printers already have a stellar reputation for reliability, engineering excellence and innovation. In line with this, Prusa offers a multi-color 3D printing upgrade for their MK3S machines, allowing you to print up to 5 different colors simultaneously.

At $300 this kit is cheaper than the Palette, but works only with Prusa printers. You can combine colors with ABS, PLA, PETG and PVA (the same as the Palette but without TPU and Nylon), and you will need to assemble the kit yourself. The kit has been meticulously tested by the Prusa team prior to release, so you can be assured of its quality.

An upgrade on the 2S compared to the previous Multi Material Upgrade is that it now features a direct drive extruder feeding system rather than a Bowden. Additionally, a filament buffer is included, which keeps each individual filament separate from others, ensuring they do not become tangled during the loading and printing processes.

Overall, it’s a fantastic multi color 3D printer upgrade kit for the already great Prusa printer line. Whereas the Palette shines in its openness and compatibility with so many common 3D printers, the Multi Material Upgrade kit encourages users to buy a Prusa and stay within this ecosystem. Both are great options for multi color 3D printing.

6. 3D Chameleon

- Price: $99 for 2 colors, $199 for 4 colors

- Color range: multi color 3D printer (up to 4 colors)

Pros

Offers 2-color and 4-color options.

Easy to assemble.

Automatically removes and reinserts each colored filament when each other is needed.

Cons

Need some understanding of how 3D printer g-code works.

A lesser known multi color 3D printer adaptor, the 3D Chameleon DIY kit offers multi extrusion with different materials or colors, and is compatible with commonly used printers by brands like Creality and Prusa.

Compatible with Bowden extruder 3D printers, 3D Chameleon offer both 2-color and 4-color options, depending on the variety of color you are looking for in your 3D prints.

The kit takes less than an hour to assemble, and doesn’t involve any technical or complex electronics. Once set up, it uses your 3D printer’s hardware to automatically remove and reinsert each colored filament when each color is needed based on your model’s specification. You can slice multi extruder models in Prusa Slicer, Slic3r, Cura and a number of other 3D slicers, and at a lower price than the Palette or Prusa adaptors, some will find the 3D Chameleon multi color 3D printer adaptor the best option for them.

Full Color 3D Printers

FDM currently offers one method for full color 3D printing. This involves using a colorless filament, with each area dyed during the melting and extruding process to deposit full color 3D parts.

This method combines elements of 2D inkjet printing with FDM 3D printing, with the same CMYK inks used to color the filament as you use in your color 2D printer at home. These inks can be easily removed and replaced as with 2D ink cartridges, offering a hybrid color 3D printing solution which most will be familiar with from their home printing systems.

An example of this technology sold today is the XYZprinting Da Vinci Color, and the Da Vinci Color Mini 3D printers. They offer full color 3D printing at affordable prices, and are the first accessible venture into full color 3D printable models.

7. XYZprinting Da Vinci Color

- Price: Check price at Amazon here

- Build volume: 200 x 200 x 150 mm

- Color range: full color 3D printer

Pros

Individual inkjet cartridges can be replaced.

Auto-calibration.

Detailed prints.

Cons

May be too expensive for some people.

Undoubtedly one of the most interesting and innovative 3D printers of the last few years, the Da Vinci Color is the only full color 3D printer around that isn’t an industrial machines costing tens of thousands of dollars.

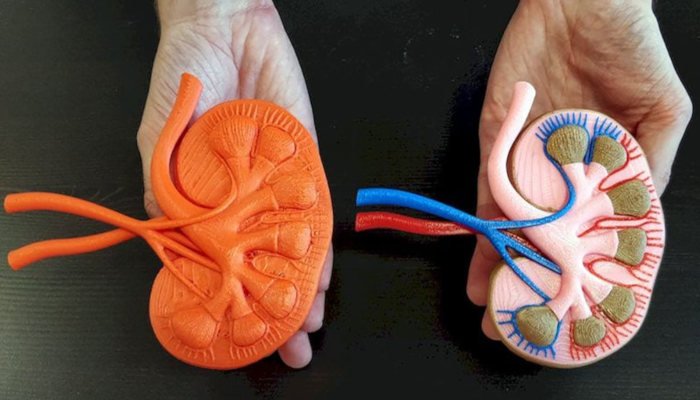

The full color 3D printing is possible as it combines standard FDM 3D printing — using a colorless PLA filament — with inkjet CMYK ink cartridges that dyes and colors the filament as it is printed. This results in detailed, full color 3D prints, with even small details captured in the correct color. This has massive advantages for communicating prototypes or designs to upper management in full color, and is also great as a 3D printer for miniatures, in the video game design, art direction, and character creation industries for films and animation.

Despite being an FDM 3D printer, the Da Vinci Color uses the same inkjet cartridges as standard 2D printers, with each cartridge being able to be individually removed and replaced in the same way, and using the CMYK color system. It prints at up to 100-micron accuracy, and features a 5-inch touchscreen for simple navigation. The Da Vinci full color 3D printer can also auto-calibrate, and can be printed via both USB and over WiFi.

Overall, it’s the only way to get full-color 3D printing on an FDM 3D printer, with other full-color 3D printing options restricted to extremely expensive technologies like PolyJet and Multi Jet Fusion. Even if the colors can look washed out, it’s a tremendous achievement to even succeed in offering full-color 3D prints on an FDM machine for under $3,000.

A Da Vinci Color is also available, with a smaller print area. It costs $1,600 and can be purchased here.

What is a color 3D printer: differences between a multi color 3D printer and full color 3D printer

When we say multi color 3D printer, we do not mean that the 3D printer can print the whole spectrum of colors, but several different fixed colors in one model. Colored filaments are printed in certain places in the model, creating parts made from a restricted number of block colors, but these colors are bold and stand out.

A full-color 3D printer on the other hand offers a complete range of colors, mixing CMYK or RGB colors so that even slight changes in color or texture are reflected in your 3D printed model. Far more color customization is available, though colors can be less bold and look more washed out.

The majority of the color 3D printers featured in this buyer’s guide are multi-color 3D printers that are able to print 2, 3, 4, or even 5 different colored filaments in one model.

The main ways to 3D print in color

For a quick introduction, these are the main ways to 3D print in color:

- Stopping and starting, changing filament: A labor-intensive and frustrating method, this involves pausing your print and changing out one color filament for another and then resuming the print. 3D slicer settings can be set to pause at the point you want to switch filament automatically. Multi color 3D printers effectively automate this with multiple colors for you.

- Using a dual extruder: Dual extruder 3D printers offer printing in two colors, or two different materials. For those satisfied with creating models printed in two different colors, you can simply load two different colors of your chosen filament, such as black and red, and print your model mixing these colors.

- Mix color systems: Used on Geeetech printers we recommend below, these systems can mix multiple filaments within your print to create prints with changing color gradients and patterns.

- Color 3D printer adaptors: We include a whole other section for these below. These adaptors splice multiple different filaments together based on which areas are to be printed in each color. You can turn single extruder 3D printers into color 3D printers using these adaptors. Popular filament splicers include the Palette range by Mosaic Manufacturing.

- Full color 3D printers: These use 2D inkjet printer inks to dye filament as it is printed, rather than feeding and extruding multiple different colors of filament at the same time. The XYZprinting Da Vinci Color we discuss below utilizes this method.

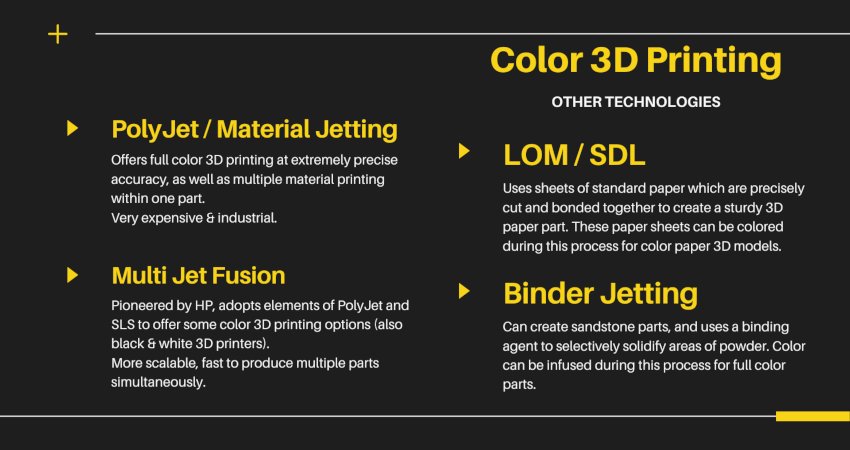

Industrial Color 3D Printing Technologies

Binder Jetting

Also known as ColorJet 3D printing, Binder Jetting 3D printers were first released by ZCorp, which was later acquired by 3D Systems. Binder Jetting 3D printers are now sold under 3D Systems’ ColorJet range.

Binder Jetting involves depositing a layer of powder, and then selectively depositing a binding agent which solidifies the layer. The binder is colored with ink during this process, allowing for full color 3D prints across the entire CMYK color palette range. The process also uses no supports, so color 3D prints come out with no markings from where supports have been removed.

PolyJet / Material Jetting

PolyJet 3D printing was first patented by Objet back in 1999, and more recently merged with Stratasys in a multi-billion-dollar deal, with Stratasys the surviving company. It is the most similar color 3D printing process to traditional 2D inkjet printing, with thousands of tiny photopolymer droplets deposited onto the build tray that can be colored any color, before being cured by a UV light.

Not only can a full range of colors be used in PolyJet, but also a wide range of different materials within a single model. This offers vast and wide customization for rapid prototyping and low-volume part production.

Laminated Object Manufacturing / Selective Deposition Lamination

A less-known 3D printing technology, LOM / SDL 3D printing involves printing and cutting up standard A4 sheets of paper according to the model’s dimensions, and binding each layer together.

Full color 3D printing can be obtained by spraying each layer with the desired color, as is shown by MCor (now known as CleanGreen3D) 3D printers. Full color, durable paper parts can be printed, and do not require supports, with finished parts easily removable from the unused paper which is die-cut during the 3D printing process.

Multi Jet Fusion

Developed and commercialized by American tech giant HP, Multi Jet Fusion is somewhat similar to Binder Jetting in that it uses fusing agent on a powder bed. This fusing agent is deposited on the areas of the part that are to be solidified. The individual areas of the part can also be colored during the process, leading to full color 3D printed parts.

Conclusion

The future of color 3D printing looks very hopeful, with adaptors like the Palette making 3D printing in color far more accessible to hobbyists on an average salary.

With patents for some more industrial 3D printing technologies expiring in the near future, there is also reason to be excited for entrepreneurs looking to make low-cost 3D printer versions of existing technologies.

This has already happened for SLA 3D printers as well as FDM — and to a lesser extent, SLS 3D printers — so we look forward to seeing if accessible PolyJet 3D printers start appearing in the next few years.