Direct Metal Laser Sintering is the most widely used metal 3D printing technology. Many major valuable 3D printing companies including 3D Systems, SLM Solutions, Concept Laser and EOS sell DMLS metal 3D printers that are able to create incredibly intricate metal parts, and 3D printed jewelry from precious metals.

This guide covers the Direct Metal Laser Sintering process, as well as requirements post print, the materials DMLS printers can use, and the advantages and disadvantages compared to other metal 3D printing processes like Binder Jetting and Electron Beam Melting.

If you found this guide useful, be sure to check out our other 3D printing technologies guides.

This guide is also part of our FREE 3D printing technologies EBook. You can download it here.

Approx reading time: 4 minutes.

Direct Metal Laser Sintering / Selective Laser Melting

Both DMLS and EBM fall under the metal Powder Bed Fusion umbrella, but have one key difference. Selective Laser Sintering also falls under Powder Bed Fusion, but only involves plastics, whereas DMLS and EBM only 3D print metals. Selective Laser Melting is also explained below.

DMLS vs SLM

DMLS and SLM (Selective Laser Melting) are also sometimes used interchangeably, but are also slightly different. In the DMLS process, metal powders are heated to a high enough temperature to fuse together to create a solid part — but are not completely melted.

In SLM however, the metal powder is completely melted, creating a homogenous part with a universal melting point and the same mechanical properties throughout the part.

While the process is the same, DMLS is used when alloys are being created for the metal parts, while SLM is used to create single element metals, such as with titanium or aluminum.

DMLS vs EBM

The technologies behind both DMLS and EBM are the same, except for how the metal powder is heated and solidified. Whereas DMLS and SLM use a proton laser to heat up the metal powder, EBM instead uses an electron beam. This focused electron beam scans across the metal powder layer, solidifying the chosen area.

- You can also view our complete guide to Electron Beam Melting here.

History of Direct Metal Laser Sintering

Direct Metal Laser Sintering was patented by ERD and EOS back in 1994, before EOS pioneered the technology in their DMLS 3D printers. Though the patent didn’t come about until 1994, preliminary research conducted on what would eventually become DMLS can be traced back to the late 1970s.

DMLS 3D Printers & Printer Characteristics

Direct Metal Laser Sintering is different to technologies such as Fused Deposition Modeling in that it doesn’t use filament. Instead, a metal powder similar to SLS is used. This metal powder has to be very fine and has a specific geometry to ensure the smoothness of parts printed using DMLS.

Metal 3D printer performance depends on three main factors:

- Laser spot size: how large the laser is and therefore how precise it is.

- Geometry of metal powder: finer powders vs less fine powders.

- Layer height: smaller layers means longer print times but better quality surface finishes and part quality.

Overall, metal 3D printers are usually accurate to around 0.1mm. They are not like desktop FDM 3D printers that are often plug and play however, and often require trained operators to monitor the machines safely and effectively.

Direct Metal Laser Sintering / SLM 3D Printing Process

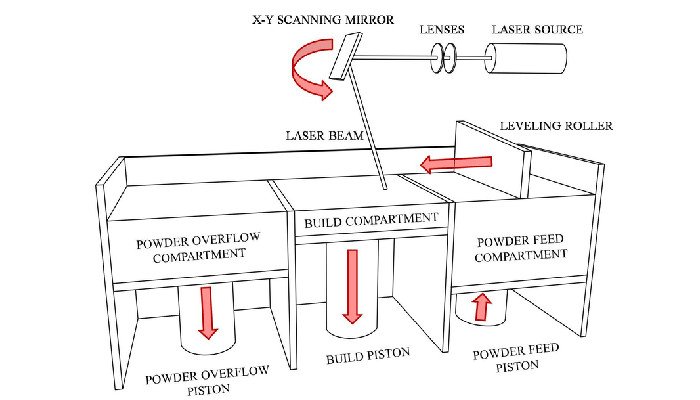

Firstly, the roller within the metal 3D printer spreads out a thin layer of powder in the 3D printer’s empty tank. This powder layer is spread to be the same as the height of one layer (usually 20-100 microns). The print chamber of the 3D printer is then heated up.

The heated print chamber heats the powder until it is not far below its melting point. The 3D printer’s laser then follows the preset shape of the 3D file design to trace the part, sintering the metal. Once the laser has finished sintering the full layer, a new layer of powder is spread again by the roller, and the process repeats. This continues, layer-by-layer, until the finished metal part is created.

If you’re looking to purchase a 3D printer for DMLS, we may be able to help:

*One of our trusted partners will be in touch following a quote request.

DMLS / SLM Post-Processing

Unlike technologies such as Fused Deposition Modeling, you cannot just remove your finished part straight after printing with Direct Metal Laser Sintering. There are additional steps before you have a functional part, and a number of optional steps for better finish quality.

1. Heat Treatment

Before you can remove the object from the build platform, heat treatments are required with Direct Metal Laser Sintering. This involves heating and cooling the object at regulated temperatures to help the part solidify and become stronger. This also helps increase the porosity of the metal.

2. Support Removal

Supports help with metal part quality in a variety of ways. Firstly, they act as a heat sink, deflecting heat from the part and minimizing distortion due to heat and printing stresses. Unlike with Stereolithography or FDM, removing supports with Direct Metal Laser Sintering is not as easy as just breaking off the plastic supports. With DMLS, the metal supports need to be broken off with machines, which can lead to problems with surface finish on these areas. These areas need to be filed afterwards.

3. Excess Powder Removal

As with Selective Laser Sintering, parts are surrounded with the material powder in the build chamber. Therefore, any excess unsintered powder needs to be removed from the part, to either be reused (if possible) or thrown away.

4. Optional Extras

- Machining – to improve surface finish.

- Polishing – shinier surface finish.

- Metal plating.

Direct Metal Laser Sintering / SLM Materials

Though 3D printer manufacturers are continuously innovating to create new metal powders, there are a number of main metal powders used in DMLS 3D printing. These include aluminum and titanium, though others such as Cobalt-chrome, Stainless steel and Inconel are also commonly used.

- We have a separate guide to 3D printing aluminum.

Direct Metal Laser Sintering can also be used with precious metals to create 3D printed jewelry. This process involves metals such as gold, platinum, or silver to create stunning pieces of jewelry with complex geometries that other manufacturing processes just cannot do.

DMLS / SLM Companies

Though new 3D printer manufacturers are entering the DMLS market every year, there are a few dominant companies in the sector. These include 3D Systems, EOS with their EOSINT range of printers, SLM Solutions, and GE Additive since their acquisition of Concept Laser.

New metal 3D printer companies threaten these incumbents however, as Desktop Metal have shown with their extraordinary growth. Others, such as XJet, Markforged, Vader Systems and Renishaw make industrial 3D printers that will compete for high value contracts.

- We also have a full guide on metal 3D printer manufacturers.

DMLS / SLM Applications

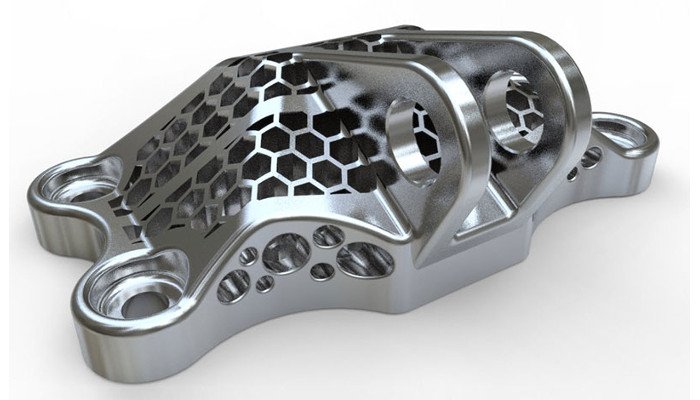

Aerospace: Direct Metal Laser Sintering is heavily used in industries such as the aerospace and automotive sectors. This is because DMLS can create parts that are optimized so they weigh far less, while retaining their strength. In industries like aerospace and also automotives where saving just a kilogram can save companies millions, DMLS offers a fantastic improvement.

Medical and dental: DMLS is also used in the 3D printed medical sector, to parts in sterile metals that can be inserted into patients to promote healthy bone growth. Metal DMLS parts have also been fairly widely adopted in the dental sector, for crowns and other implants.

Direct Metal Laser Sintering Advantages and Disadvantages

DMLS Advantages

- Great for creating geometrically complex parts where much customization is required. DMLS is a great alternative when other manufacturing methods simply cannot create parts with certain geometries.

- In addition

- Can create strong metal parts: parts have good mechanical properties, far better than those of binder jetting.

- Offers significant benefits through topology optimization, reducing weight and increasing strength of rockets, planes, and cars. This is why 3D printing has seen significant use in Formula 1, where the milliseconds gained can mean the difference between the podium and glory.

DMLS Disadvantages / Limitations

- DMLS offers a small build size compared to other technologies. Other technologies such as FDM can offer build sizes of over 100cm³ which DMLS cannot compete with.

- DMLS is a very expensive process. All metal 3D printers are industrial and can cost $250,000+. In addition, metal powders are extremely expensive, with stainless steel 316L powders costing $350-450/kg. Binder Jetting several times cheaper, though it is not as accurate.

- Designing lattice structures for DMLS is difficult because it can only span around 2mm before needing supports.