Is PLA or ABS not cutting it anymore? For something more durable that can handle higher temperatures than PLA, but is easier to print than ABS – PETG is the filament for you!

PETG filament is a tough, durable, and flexible material ideal for printing large and flat objects.

It’s the perfect material for prints that require durability to resist impacts, with excellent chemical and water resistance.

That said, it’s important to know that PETG is incredibly adhesive. This means prints can be tricky to pry from the print bed, and it’s a poor choice for supports that you intend to remove from your finished print.

So whether PETG is right for you is going to depend entirely on the nature of your project.

In this guide, I’ll explain all of the strengths and weaknesses I’ve found in my experience using PETG, along with its ideal use cases and some tips and tricks to produce perfect prints with this filament.

After reading this guide, you’ll be getting the best possible prints using PETG and able to advise on when best to use this great material.

What is PETG Filament?

PETG is a durable copolyester (a combination). The PET stands for polyethylene terephthalate (think plastic bottles) and the G means it’s been glycol modified for extra durability.

One great thing about PETG is that it is very recyclable – so as long as the material is processed correctly, it can be repurposed fairly easily.

The flip side of that, however, is that PETG is (mostly) non-biodegradable, meaning it isn’t broken down by bacteria or living organisms. This, depending on how the plastic is being used, can be seen as a pro or a con.

PETG Characteristics

In short, PETG is a really tough material – it’s extremely durable and prints without odor. Once you’ve dialed in the correct print settings, it prints nicely too. Users report similar finish quality to PLA.

Here are the main benefits of 3D printing with this material and common PETG filament properties:

- Very durable, it’s more flexible than PLA or ABS, but also a little softer. You’d have a hard job breaking it in half, so if an ‘unbreakable’ case or enclosure is what you need, PETG trumps pretty much everything (except, Nylon 12).

- It has very low shrinkage, and therefore no warping. Ideal for printing big stuff.

- PETG is also very strong, it’s not brittle but can be scratched more easily than ABS which is harder.

- PETG plastic makes a terrible support structure because it sticks so well. But because it sticks so well, layer adhesion is fantastic, so prints come out strong. If you are having trouble with adhesion, read our PETG adhesion guide.

- It sticks well to the print bed too, so be careful when you’re removing it after printing.

- It has great chemical resistance, along with alkali, acid, and water resistance.

- Odourless when printing.

Typically Polyethylene filament is supplied in a range of translucent colors, and prints with a nice glossy finish.

It makes it ideal for printing anything that needs to be shatterproof or translucent. Many are taking the leap from using PLA or ABS to just using PETG.

PETG has quickly become an extremely popular material due to its advanced properties, ease of printing and color range. It usually is the next step in material experimentation after PLA due to its increased temperature resistance and toughness, and it can be printed on most printers, from desktop to professional.

Compared to other popular, slightly more difficult materials to print (I’m looking at you, ABS!), PETG can provide a great solution to prints that need to be functional. It has high impact resistance, meaning it can be dropped, hit, and generally take a bit of battering without breaking. If you’re not convinced, try and break a plastic water bottle and see for yourself how durable this material truly is!

What is PETG Best for in 3D Printing?

Because of how easy PETG is to print nowadays, there aren’t many situations where we would turn down the material, but there are some solid examples of when we would say “ah yes, PETG is the one to use”.

PETG is considered food and drink safe, and is often used for waterproof parts and parts that will come into contact with food. Additionally, because of its great bed adhesion and very little warping, long and flat parts are often best 3D printed in PETG, such as mechanical parts.

Owing to PETG’s strong impact resistance, durability and density, PETG is the filament of choice for many makers creating custom parts for drone projects or other remote-controlled electronic experiments. Additionally, 3D printer parts are sometimes made from PETG, among other protective casings for electronics and motors as PETG can handle heat reasonably well.

The main argument for PETG is that it is strong and sturdy and has very low shrinkage – meaning you can print very accurate, large prints. It also has good heat and chemical resistance, making it great for the following projects:

- Medical items

- Engineering pieces

- Electric cases

- Functional items

- Jewelry

- Models with moving part

But we don’t recommend printing everything with it, due to its flexibility (which isn’t always desirable, depending on your application).

What’s PETG’s Glass Transition Temperature?

PETG has a glass transition temperature of 80°C – so that’s worth taking into consideration when deciding what material to make your next project out of. This is significantly lower than ABS’s Tg of 105°C, but higher than PLA which is as low as 55°C.

Below is one of our customer’s applications, which is a bumper for his micro quadcopter. As you can imagine, the bumper needs reasonable stiffness to resist impacts, but yet plenty of durability to absorb the force of any severe crashes.

We think this is a perfect example of the types of prints you may wish to print with this material. Essentially, it’s a great addition to your existing 3D printing filament arsenal.

Here are a few data stats about PETG:

- Density of 1.27g/cc, that’s just higher than PLA and about 20% denser than ABS.

- Rockwell hardness of R 106, which is pretty high for PETG. (Our ABS, which is very hard, is rated R 110.)

Now you know why you’re likely to go for PET-G filament vs the more traditional materials. It’s nice to print with and produces excellently tough prints that will last.

Let’s look at how to get the best results from this underutilized filament, so that you can spend the least amount of time setting up, and more time producing ultra-durable high-use prototypes, models, or end-use parts.

Here’s How to 3D Print PETG

As with all 3D printing materials, you need to take note of the specific traits that material adheres to – which issues are caused by what?

This always saves head-scratching time when you run a material through your printer the first time, and the results aren’t quite what you expected.

This plastic is just like any other, you just need to adhere to the few best practices when printing and you’ll love the results.

Sometimes PET-G can take a little more setting up, fine tuning those filament settings. It’s just slightly more particular than something more forgiving, like PLA. That’s not to say it’s hard to use, just perhaps a little more patience with the setup.

But once you’re set up correctly, you’ll find printing with PETG a dream. No warp, odorless printing and great layer adhesion are just some of the excellent properties with printing this filament.

Be sure to use a high-quality polyethylene filament and it’s likely you’ll just dial in your PETG temperature settings and you’ll be away.

However, as with any filaments there are some pointers to make the new transition easier.

Let’s look at how to get setup correctly, issues to look out for and our top PETG printing tips that’ll save you time troubleshooting.

PETG 3D Print Settings

PETG Temperature Settings

We recommend printing PETG settings at roughly 220°C-245°C depending on your extruder. The PETG bed temperature works best around 70-75°C, a few degrees hotter perhaps for those first few layers.

What’s the Best Surface to Print PETG on?

In our experience, blue painter’s tape works the best for 3D printing PETG. A very old method of print surface but, if it ain’t broke, don’t fix it!

PETG generally has no trouble sticking to your print surfaces. It can be a bit of a pain when it comes to bed adhesion – but not in the way that you may think! On standard surfaces, the material can stick TOO well! Removing your prints then becomes a tricky game of applying enough force to get the print off but not too much so that it ruins the print surface, or worse, the printer itself.

PETG Retraction Settings

This material doesn’t need to be squeezed onto your heated bed, you want to leave a slightly larger gap on the Z-axis to allow more room for the plastic to lay down.

If the extruder nozzle is too close to the bed, or the previous layer, it will skim and create stringing on your PETG and build-up around your nozzle. We recommend starting off moving your nozzle away from the bed in 0.02mm increments, until there is no skimming when printing.

PETG Fan Settings

When setting your print cooling fan, the general rule is: the less fan, the better the layers bond and the higher the strength – but the worse the finish will be due to stringing and poor overhang printing.

The more fan, the weaker the bond (it will still be good just not great) but the better the finish on perimeters, top surfaces and overhangs.

A good compromise is a range between 30% and 60% fan speed. If you have a part that has lots of bridging sections, it is recommended to have a higher fan percentage, for these sections, so you do not allow the molten material to sag too much before cooling. This is easy to set up as most slicers enable you to set a fan speed override for bridges.

This is the sort of thing you may choose different fan settings for different prints – so that you’re set up optimally for what you wanted to print. Experiment to get a good idea for how the filament reacts with your printer’s fan settings.

PETG Print Speed Settings

As with a lot of materials, PETG likes to be printed slow. Printing slower than 60mm/s is recommended to give PETG time to bond with previous layers and cool sufficiently in overhangs and bridged sections. If you print faster, quality and structural integrity may be compromised.

General Best Practices

One downside of printing with PETG is that it can end up gathering wayward pieces of filament during the printing process and can build these up to form little clumps of molten material.

These little clumps can then be deposited on your print in unexpected places which will at best ruin the overall finish of your print, or at worst, disrupt your print, cause collisions or ruin dimensionally-critical areas.

Fortunately, there are a few methods to avoid or reduce these imperfection:

- Increase retraction to reduce stringing and leaking material

- Enable the “wipe” setting

- Under-extrude slightly, but not by a huge amount. 0.1-0.2% is a good starting point(this will also help with stringing)

- Increase cooling fan speed (but as mentioned earlier, this does come at a cost of lower strength)

It’s likely you won’t have issues with all of these points, but as you can see – just like other 3D printing filaments, each material has its own set of traits to set up for.

Once you know the cause of each issue, and how to fix you’ll find the printing consistent time and time over.

Best PETG Filament

For every day, entry level 3D printer hobbyists who want to experiment and have fun, basic low-cost PETG will suffice. Those looking to make high quality parts with rapid prototyping may instead be drawn towards industrial 3D printer PETG filament, costing more.

- Matterhackers USA PETG filament range

- Matterhackers USA PRO Series PETG

- 3DJake UK & Europe PETG range

Here’s a Quick Rundown of PETG vs ABS:

- PETG is more durable than ABS, but ABS is harder, and more rigid.

- PETG glass transition temperature is lower, at 80C compared with ABS’s 105C

- ABS is approximately 20% less dense than PETG.

- PETG won’t warp like ABS might (if printed incorrectly) and is generally odourless.

- PETG is more chemically resistant, and so cannot be acetone smoothed like ABS.

Read more: PETG vs ABS – in-depth comparison

Here’s a Quick Rundown of PETG vs PLA:

- PLA filament strength is more brittle than PETG, unless you want to try to anneal it.

- PLA and PETG have very similar densities.

- PETG will need a heated bed, whereas PLA can be printed cold.

- Layer adhesion with PETG is typically unmatched, leaving very strong and durable prints.

- PLA prints supports easily to remove, whereas these are harder (but not impossible) to remove with PETG.

Read more: PETG vs PLA – filaments compared

TOP TIP: If you switch back and forth between PLA and PETG on your printer, beware that a nozzle that’s contaminated with PLA will not print PETG well – the PLA will interfere with bonding and the layers of PETG won’t stick together. If your PETG prints start out weak and crumbly for the first few layers and then become solid and strong for the rest of the print, contamination is the likely cause. To avoid this, when switching from PLA to PETG make sure you purge the nozzle with enough PETG to get rid of every last remnant of PLA from the printer’s hotend. It’s also a good idea to use a brim, skirt or raft so those risky first few lines aren’t part of your final prints.

How to Store PETG

PETG is slightly hygroscopic, meaning it absorbs small amounts of moisture from the air which worsens the print quality of PETG parts over time, making them more brittle and bubbly. It is recommended to keep all filament in a good filament storage container or other protector, or at least in a dry part of the room.

You can also dry “wet” PETG with a filament dryer. This helps remove most of the moisture and avoids most of the downsides that occur if you leave filament out for too long.

We recommend the following products:

- PrintDry Filament Drying System — dries wet filament, improving part quality

- PolyMaker Filament Storage Box II — for good storage and safe printing

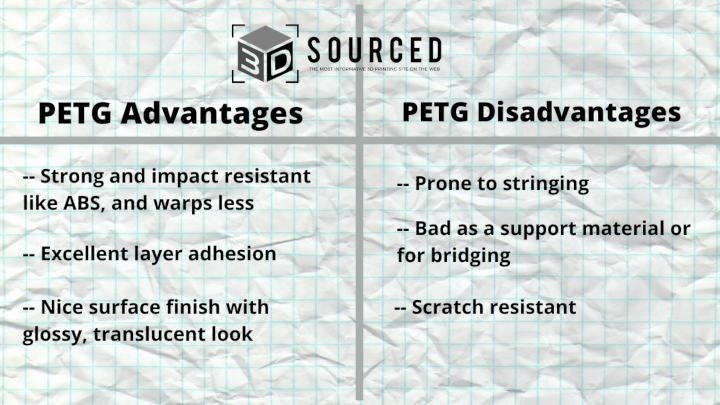

Advantages and Disadvantages of PETG

Advantages of PETG Filament

- Great middle-ground between PLA and ABS: PETG is stronger and can handle higher temperatures than PLA, while warping less than ABS.

- Excellent layer adhesion without much warping: PETG’s stickiness gives it great adhesion to the print bed, leading to strong, durable parts. This makes PETG a great option for long and thin parts that are very difficult to print using filaments like ABS.

- Good surface finish: PETG prints come out glittery and glossy, with a translucent, radiant finish. Though not to everyone’s tastes, many enjoy the finish they get from PETG 3D printing.

- Odorless: unlike ABS, PETG does not create bad smells from fumes while 3D printing.

- Many color options: like ABS and PLA, there are many options to choose from with PETG, so you’ll never struggle to find the blend you want for a particular project.

Disadvantages of PETG filament

- Poor for supports or bridges: the excellent layer adhesion comes at a cost: PETG supports can stick too well, creating difficult-to-remove supports that can leave marks on the part. If you have a dual extruder 3D printer, consider printing a different support material like PLA that is easier to remove.

- Can string, worsening surface finish: make sure to fix your retraction settings as otherwise strings or hairs can affect the surface finish of your prints, and are generally annoying. Research good 3D slicer settings for your desired results.

- Bad scratch resistance compared with ABS: the glycol that enhances PETG from PET in so many ways makes it less scratch resistant, so over time parts can wear down and look less aesthetically pleasing.

- Difficult post-processing: the chemical resistance is also an advantage, but means PETG can’t be acetone polished like ABS can for a better surface finish. PETG’s natural glossy finish means this isn’t a big downside however, and it can still be sanded.

PETG Frequently Asked Questions

Related articles:

- Best Glues For PETG (Gluing PETG Parts)

- PLA filament guide

- ABS filament guide

- PLA vs PETG

- ABS vs PETG

- PLA, ABS, and PETG shrinkage: Everything you need to know